CO NABÍZÍME?

Technologie v naší výrobě:

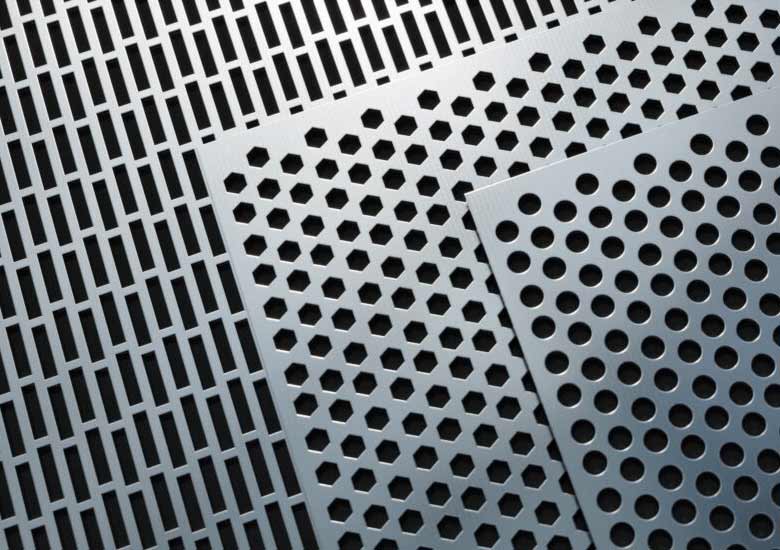

Naše technologie umožňují široké možnosti CNC zpracování plechu díky kombinaci CNC vysekávání, tváření, ohraňování a lisování. Zajistíme pro vás i svařování a povrchové úpravy.

8 let na trhu.

5 000 000 dílů.

Už od roku 2016 dodáváme plechové díly do významných podniků působících v regionu, především z oblasti strojírenského průmyslu a stavebnictví.

Náš příběh je od počátku spjat se společností KONE, světovým lídrem v oboru výtahů a eskalátorů. I díky tomuto partnerství máme zaveden robustní systém řízení jakosti a plníme přísné požadavky na kvalitu a procesní podporu.

Od jednorázových zakázek až po sériovou výrobu.

Ve 4MEXu nabízíme řešení na míru. Základem naší výroby jsou velké série, které doplňujeme zakázkovými projekty. Naši technologové jsou připraveni vás provést procesem prototypování nového výrobku a následně zajistit výrobu plechových dílů na klíč.

Na prvním místě kvalita a termíny.

Jsme dlouholetým dodavatelem do společností, v jejichž odvětví jsou zvýšené nároky na bezpečnost, přesnost a kvalitu. Tomu přizpůsobujeme naše procesy a prostředí. Dbáme na domluvené termíny, jsme kompatibilní s just-in-time přístupem.

Špičkové vybavení

Základem naší výroby jsou moderní CNC stroje značky TRUMPF. Aktuálně využívámě dvě výseková centra TruPunch a dva ohraňovací lisy TruBend v různých specifikacích.

Komplexní služby

Podpoříme vás ve všech fázích výrobního cyklu - od návrhu, přes prototypování, až po kompletní výrobu, povrchové úpravy a montáž. V rámci skupiny máme i vlastní autodopravu.

Flexibilní přístup

Z pohledu přístupu zůstáváme rodinnou firmou. Naši zákazníci oceňují flexibilitu, s jakou se snažíme vyhovět jejich požadavkům, a která není v korporátním prostředí standardem.